PARKING VENTILATION

EFFECTIVE AND ECONOMICAL SOLUTIONS

Parking ventilation systems consist of the jet fans, panels that control these fans and circuit control systems.

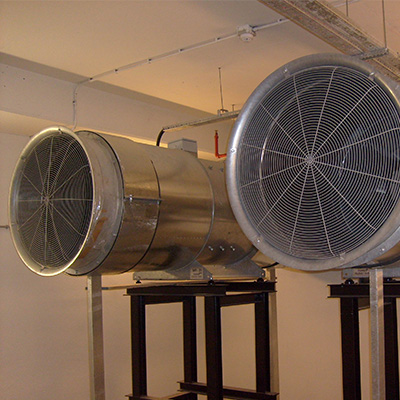

JET FANS

Proper smoke control for safety

Jet Fans work with the principal of pushing the air masses at discharge opening with the high air velocity they create and mobilize with the induction principle. Strategically located jet fans inside the parking space remove the harmful exhaust gases during daily use and drive the smoke to the shafts in case of a fire, helping people escape and the fire squad work safely. EN 12101-3 compliant with 2 hours fire resistance.

Jet Fan Technical Specifications:

- Blades are cast aluminum. Adjustable blade angles. Dynamically balanced according to VDI 2060 / ISO 1940/1-1986.

- Deflectors can be used for precise air flow direction, depending upon architectural conditions.

- The complete casing is manufactured as a silencer. The fan motor and impeller are slid into the casing. This feature minimizes noise emitted from orifices and the shell.

- Blades are cast aluminum. Adjustable blade angles. Dynamically balanced according to VDI 2060 / ISO 1940/1-1986.

- Deflectors can be used for precise air flow direction, depending upon architectural conditions.

- The complete casing is manufactured as a silencer. The fan motor and impeller are slid into the casing. This feature minimizes noise emitted from orifices and the shell.

AXIAL FANS

Manufacturing according to ISO 9001 standards.

Suitable for assembly inside or outside fire zone at standard temperature or 300°C during 2 hours (EN 12101-3 F300 class) depending upon project details, at specified flow rate and static pressure.

- Fans are inside long, self-flanged cylindrical casings in such a way that completely encloses the motor and impeller.

- Fan blades and hub are precisely pressure cast from aluminum.

- Blade profiles are aerofoil to ensure high efficiency and silent operation.

- Blade angles are adjustable at the field as required.

- Fans that are designed to work at standard temperature have IP 55 – Class F motors and those at high temperature (EN 12101 – F300 / 300°C – 2 hours) or “F400 / 400°C – 2 hours” have IP 55 – Class H motors.

- Fan casings hold high temperature resistant terminal boxes. Connections and wiring between the motor and the terminal box are designed and manufactured to resist high temperatures as well.

- Manufacturing fully complies with ISO 9001

JET FAN CONTROL PANELS

Combined automation and power panels.

Jet fan control panels are combined automation and power panels that are designed to realize previously programmed system scenario during daily ventilation of in case of fire.

It controls the following components in the jet fan system:

- Shaft fans at two speed or frequency converted depending upon need.

- Jet fans at two speed

- Open and close dampers in the system, according to the scenario

Equipment and properties listed below exist on the panel:

- Fire situation reset button on the casing

- Light indicator on the casing for stand-by / Malfunction / CO modes

- The signalization enlisted below can be given by means of dry contact

- Signalization for CO detection system

- Signalization for fire alarm system

- System monitoring from BMS (Stand-by / Malfunction / CO / Fire etc.)

Panels are made in Turkey according to IEC-439-1.

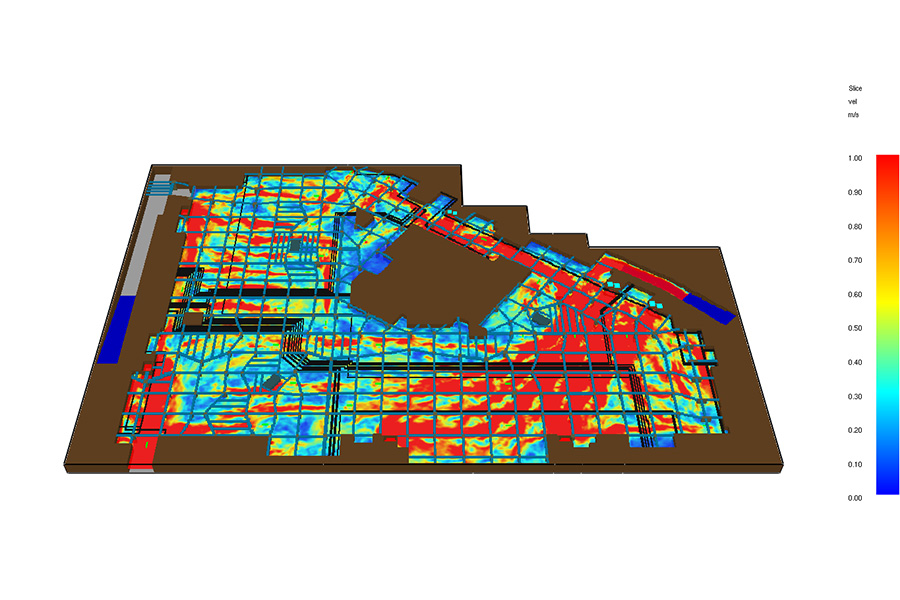

PROJECT DESIGN AND CFD SIMULATION

Fresh Air and Synchronization Ventilation Calculation

Ventilation calculations are made in parking spaces, which must be mechanically ventilated by legislation, in order to remove harmful gasses/dust and supply fresh air, considering all stories and the synchronization factor. Smoke extraction system is designed assuming the fire will start at the story with the highest volume and determining required smoke flow rates.

- Fan location and parking space fan layout drawings are prepared

- Fan activation and operation diagrams (switching diagrams) are prepared

- All electrical and wiring diagrams of the control panels are prepared.

- Fan room installations and drawings are prepared.

COMMISSIONING AND COLD SMOKE TEST

Sustainable and safe ventilation

All system components listed below must be ensured for correct connections during assembly, so that jet fan equipped parking ventilation system can work as required and maintenance can be carried out during the life time of the system.

- Main axial exhaust and fresh air fans in shafts

- Jet Fans

- Shaft dampers and by-pass dampers

- Jet fan system panel

Unless a revision or correction is required with regards to electrical or mechanical installation, the system shall be tested manually both for daily usage and fire. Cold smoke test ensures the system works according to the target scenario. System commissioning is complete following training of the personnel at customer facility.